Lamers System Care B.V. launches Service Agreement with two ferries for a commitment of three years.

Extending the life expectancy of equipment leads to more cost effective and sustainable practices. With our service agreement it’s not only our system’s life expectancy that is extended, but the protected areas are deteriorate less quickly due to less fouling wear.

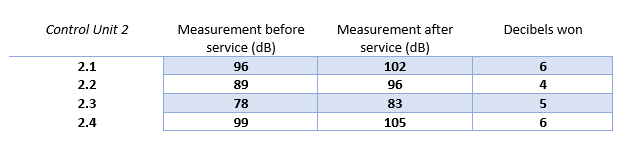

To ensure optimal transmission of ultrasonic sound waves into the protected structure a coupling agent is applied to the transducer membrane. Sound Pressure Level (SPL) measurements can be taken to show the sound transmission gained after service. The table below shows real results from decibels measured before and after the coupling agent was refreshed. The transducers in the example are placed on box cooler lids and box cooler inlets. When looking at the results it’s important to note that the decibel scale is logarithmic. This means the sound energy doubles when the decibels increase by 3. When the decibels increase by 10 the sound pressure increased by a factor 10.

At LSC we believe transparency is crucial to building a trusting relationship with our customers. In addition to the SPL measurements we offer endoscope inspections in pipework and reports of the actions undertaken during service.

The Ultrasonic Antifouling system prevents fouling from occurring. To do this the system must always be functional. A key part of the service agreement is the ability to monitor the system remotely. If a system error occurs it is crucial we act quickly to resolve the error before the biofilm forms. We pride ourselves on our 24/7 monitoring of our systems to make sure our customers are always protected against fouling.

Interested in our Service Agreement and the different options? Please contact us at info@LSCare.nl.